Filastik PE Pipe Extruder Machine

Bayani

Ana amfani da PE extruder a cikin polyethylene extrusion don extrude PE, polyolefin da sauran thermoplastics.

Polyethylene extrusion inji iya aiwatar da kowane irin roba kayayyakin da m inji damu, kamar fim, bututu, mashaya, faranti, zaren, kintinkiri, insulating Layer na USB, m kayayyakin da sauransu.

Na'urar extruder na polythene ya ci gaba kuma ƙarfin samarwa yana da girma. Hdpe ldpe extruder inji plasticization ne mai kyau, kuma ldpe extruder inji makamashi amfani ne low. Yana ɗaukar fuskar haƙori mai ƙarfi na kayan aiki don watsawa, yana da fa'ida daga ƙaramin amo, aiki mai laushi, babban kaya, tsawon amfani da rayuwa da sauransu.

Aikace-aikace

PE water & Gas PIPE EXTRUSION.

PE extruder ne yafi amfani da polyethylene extrusion for bututu, takardar, mashaya da sauran roba kayayyakin daga PE abu sanye take da daban-daban irin inji da kuma ƙasa.

Domin SJ serial dunƙule extruder, da dunƙule diamita ne daga 20 zuwa 200mm, da dunƙule L / D ne 10-40. Kuna iya zaɓar nau'in extruder bisa ga samfuran ku, ƙayyadaddun bayanai da ƙarfin ku.

Tsarin ciyarwa yana amfani da YASKAWA .kuma babban ɗaukar hoto yana ɗaukar sassan Japan NSK na asali da aka shigo da su, mai fitar da kaya yana da ƙimar kuɗi mai kyau.

Amfanin Gasa

Amincewar haɗi: tsarin bututun polyethylene da aka haɗa tsakanin amfani da hotmelt na lantarki, ƙarfin haɗin gwiwa ya fi ƙarfin jikin bututu.

Kyakkyawan juriya mai ƙarancin zafin jiki: ƙarancin zafin jiki na ƙarancin zafin jiki na polyethylene na iya kasancewa cikin kewayon zazzabi na ƙasan sifili 60 zuwa 60 ma'aunin ma'aunin celcius amintaccen amfani. Gina a cikin hunturu, saboda kayan aiki, juriya mai tasiri yana da kyau, tube embrittlement ba zai faru ba.

Kyakkyawan juriyar fatattakar damuwa: HDPE yana da ƙarancin rata mai hankali, ƙarfin ƙarfi mai ƙarfi da ingantaccen ƙarfin hana ɓarna, juriya ga aikin fashewar yanayi shima sananne ne.

Kyakkyawan juriya ga lalata sinadarai: HDPE bututu na iya zama juriya ga nau'ikan kafofin watsa labarai na sinadarai, lalata, abubuwan sinadarai waɗanda ke wanzu a cikin ƙasa ba za su haifar da lalata bututun ba. Polyethylene shine insulator na Wutar Lantarki, ba zai faru ba rot, tsatsa ko al'amuran lalata na lantarki; Bugu da ƙari, ba zai inganta algae, kwayoyin cuta ko ci gaban fungal ba.

Anti tsufa, tsawon rai: wanda ya ƙunshi 2% zuwa 2.5% na daidaitaccen rarraba baƙar fata na carbon a cikin bututun polyethylene na iya zama ajiyar waje ko amfani da shekaru 50, ba za a iya fuskantar lalacewar ultraviolet ba.

Abrasion juriya: HDPE bututu da kwatancen gwaje-gwaje sun nuna juriya da juriya na karfe bututu, HDPE bututu 4 sau juriya na karfe bututu. A cikin filin sufuri na laka, idan aka kwatanta da bututun ƙarfe, HDPE bututu yana da mafi kyawun juriya, wanda ke nufin cewa bututun HDPE yana da rayuwa mai tsayi kuma mafi kyawun tattalin arziki.

M kyau: HDPE bututu m sa shi sauki tanƙwara, aiki ta canza bututu na iya zama wata hanya ta kewaye cikas zuwa ga, da kuma a lokuta da dama, da m bututu kayan aiki don rage amfani da rage shigarwa farashin.

Juriya gudana: HDPE bututu yana da santsi na ciki, da Manning coefficient na 0.009. Ayyukan aiki mai santsi da kaddarorin mannewa suna tabbatar da bututun HDPE yana da mafi girma fiye da ƙarfin watsa bututun gargajiya, amma kuma yana rage asarar matsa lamba na bututu da amfani da ruwa.

Bayanan Fasaha

|

Samfura | L/D | Iya aiki (kg/h) | Gudun juyi (rpm) | Motoci (KW) | Tsayin tsakiya (mm) |

| SJ25 | 25/1 | 5 | 20-120 | 2.2 | 1000 |

| SJ30 | 25/1 | 10 | 20-180 | 5.5 | 1000 |

| SJ45 | 25-33/1 | 80-100 | 20-150 | 7.5-22 | 1000 |

| SJ65 | 25-33/1 | 150-180 | 20-150 | 55 | 1000 |

| SJ75 | 25-33/1 | 300-350 | 20-150 | 110 | 1100 |

| SJ90 | 25-33/1 | 480-550 | 20-120 | 185 | 1000-1100 |

| SJ120 | 25-33/1 | 700-880 | 20-90 | 280 | 1000-1250 |

| SJ150 | 25-33/1 | 1000-1300 | 20-75 | 355 | 1000-1300 |

Single Screw Extruder

Dangane da 33: 1 L / D rabo don dunƙule zane, mun ɓullo da 38: 1 L / D rabo. Idan aka kwatanta da 33: 1 rabo, 38: 1 rabo yana da amfani na 100% plasticization, ƙara yawan ƙarfin fitarwa ta hanyar 30%, rage yawan amfani da wutar lantarki har zuwa 30% kuma ya kai kusan aikin extrusion na layi.

Simens Touch Screen da PLC

Aiwatar da shirin da kamfaninmu ya haɓaka, da Ingilishi ko wasu harsuna don shigar da su cikin tsarin.

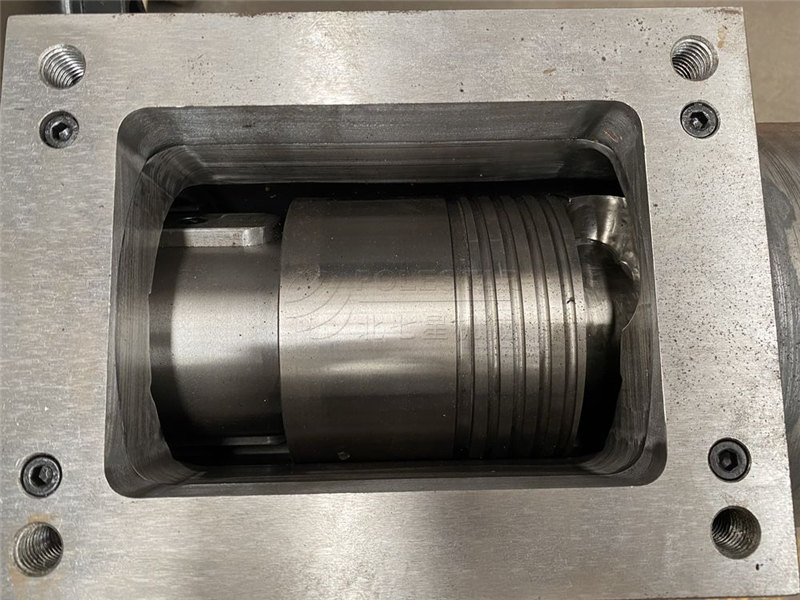

Zane na Musamman na Screw

An tsara dunƙule tare da tsari na musamman, don tabbatar da ingantaccen filastik da haɗuwa. Abubuwan da ba a narkewa ba ba za su iya wuce wannan ɓangaren dunƙule ba, mai kyau filastik extrusion dunƙule.

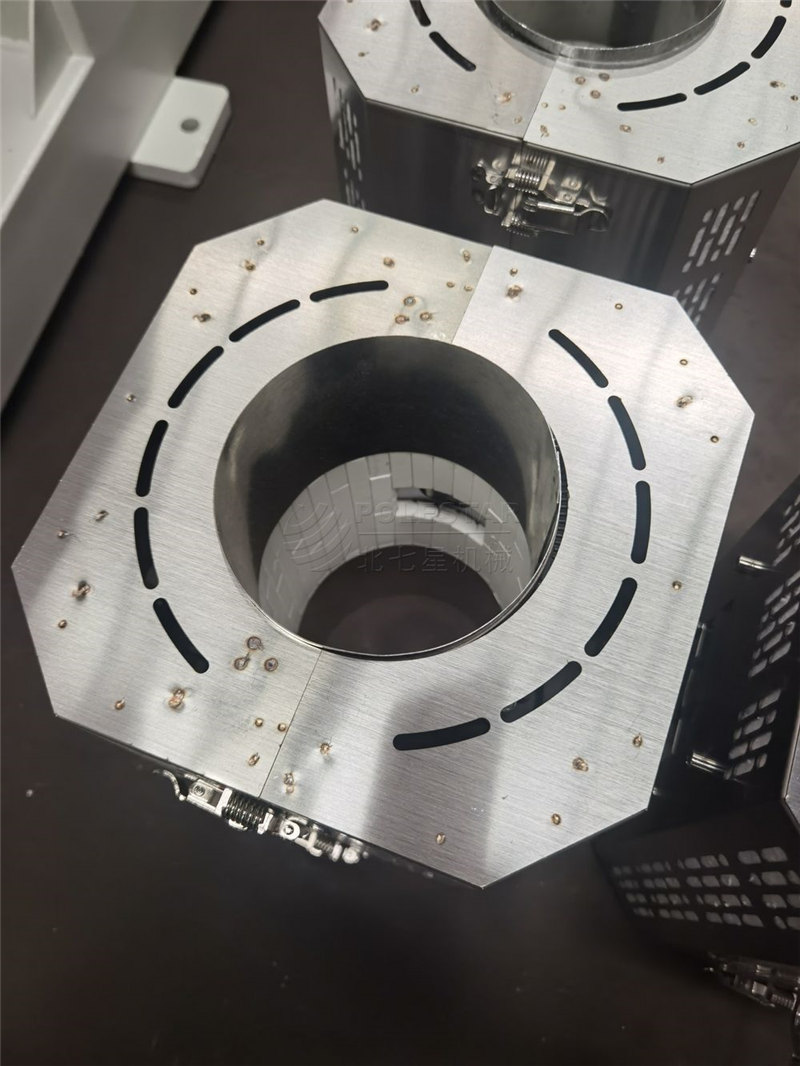

Karkataccen Tsarin Ganga

Sashen ciyar da ganga yana amfani da tsarin karkace, don tabbatar da ciyarwar kayan cikin kwanciyar hankali da kuma ƙara ƙarfin ciyarwa.

Tushen yumbu mai sanyaya iska

Injin yumbu yana tabbatar da tsawon rayuwar aiki. Wannan ƙirar ita ce haɓaka wurin da mahaɗar ke hulɗa da iska. Don samun sakamako mafi kyawun sanyaya iska.

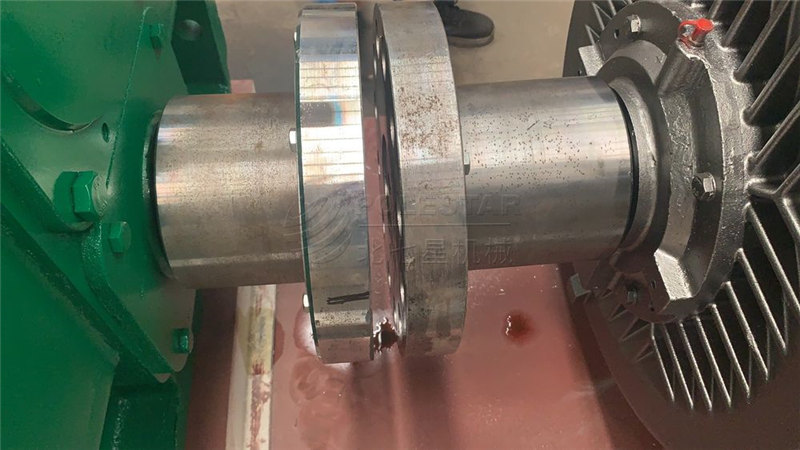

Akwatin Gear Mai inganci

Za'a tabbatar da daidaiton gear 5-6 da ƙaramar amo ƙasa da 75dB. Karamin tsari amma tare da babban juyi.

Rukunin samfuran

Kuna son Ƙara Sky zuwa Zanen ku?

Tuntube mu a yau don shawarwarin ƙira.