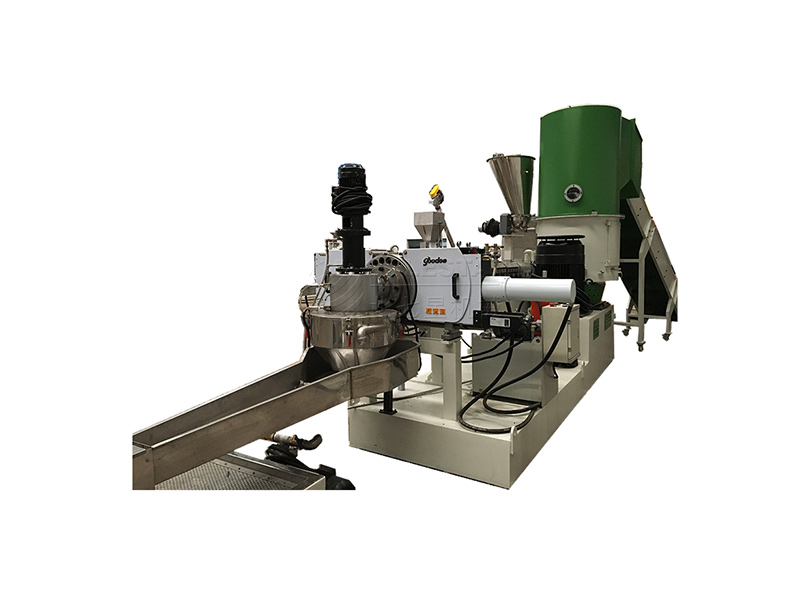

Fasahar Jamus Filastik PE PP Granulating Machine

Cikakkun bayanai

POLESTAR roba pelletizer inji / Filastik Granulators da cewa samar da uniform dumama rarraba da homogenization shi ne manufa domin samar da filastik pellets a sake amfani da tsari. Ana samun injin pelletizer na filastik a cikin guda ɗaya (na'urar extrusion guda ɗaya kawai) da tsarin tsari sau biyu (na'urar fashewa ɗaya da ƙaramin injin extrusion na sakandare ɗaya). Ana ba da shawarar cewa a yi amfani da ƙararrakin mataki biyu don aiwatar da sake amfani da su saboda gurɓacewar kayan filastik. Hakanan akwai zaɓuɓɓuka daban-daban na fasahohin pelletizing ɗin filastik da ake samu kamar su na'ura mai canza allo da mai canza allo-piston don tabbatar da cewa babu wani tsangwama yayin canjin allo. Akwatin kayan aikin mu abin dogaro yana tuƙi cikin nutsuwa don haɗawa da motsa narkakkar filastik a cikin ganga. Ƙarfe da aka yi da ƙarfe na musamman yana tabbatar da lalata da lalata. Tsarin kula da zafin jiki na PID tare da iska ko tsarin sanyaya ruwa yana kula da tsayayyen zafin jiki. "Yanke mai zafi" ruwan zobe mai mutuƙar fuska pelletizing da "Cold Cut" hanyoyin pelleting suna samuwa dangane da abin da kuke so.

Aikace-aikace

Raw material: PE, PP Films da jakunkuna

Filastik granulator inji / filastik pelletizing inji / filastik pelletizer inji tare da agglomerator za a iya amfani da PE / PP fim ko PP saka jaka da wasu parabolic pellet sake yin amfani da, da kayan za a matsa more tightened da agglomeration wanda zai zama da sauki jefa zuwa extrude zuwa extrude, wanda zai iya cimma matsakaicin iya aiki 100-100kg / hour (ya dogara da bukatun abokan ciniki)

Amfanin Gasa

1. Babban matakin sarrafa kansa, gwada mafi kyau don rage farashin ku akan aiki kuma tabbatar da babban ƙarfin aiki.

2. Tsarin kula da abokantaka (PLC hadedde & raba iko a kan kowane inji) da kuma Touch allon panel, sauki don aiki, saka idanu da gaggawa tasha.

3. Duk sassan da ke tuntuɓar kayan filastik da ruwa an yi su ne daga bakin karfe 304 mai inganci; Tabbatar cewa babu gurɓataccen gurɓataccen ruwa na biyu.

4. Siemens contactor, RKC zazzabi mai kula

Babban Siffofin

1. Maɗaukakiyar atomatik, kulawar abokantaka mai amfani, ingantaccen inganci, kare muhalli da ceton makamashi;

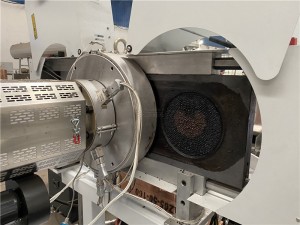

2. Daban-daban pelletizing hanyoyi, kamar sanyi strand, ruwa-zobe, da kuma karkashin ruwa ga daban-daban albarkatun kasa da kuma samar da bukatun;

3. Multi-tashoshi allon canza fuska da atomatik allo canza zane iya rage manual aiki da kuma inganta aiki saukaka;

4. Single da sau biyu mataki, Multi-exhaust da tace tsarin tabbatar da inganci da samfurori;

5. Ya dace da sarrafa kayan aiki daban-daban, kuma na iya ƙirƙira injin na musamman don abu ɗaya ko kayan daban-daban, wanda zai iya rage farashin saka hannun jari na abokin ciniki.

Bayanan Fasaha

Single mataki agglomeration granulation line

| Samfura | 70 | 100 | 120 | 150 | 180 |

| Fitowa (kg/h) | 70-120 | 200-250 | 300-400 | 500-600 | 700-850 |

| Amfanin wutar lantarki (kWh/kg) | 700-850 | ||||

| Babban iko (kW) | 37 | 90 | 110 | 132 | 185 |

| Agglomerator ikon (kW) | 30 | 55 | 75 | 110 | 132 |

| Diamita na waje (L/D) | 70 (33:1) | 100 (30-35:1) | 100 (30-35:1) | 100 (30-35:1) | 180 (30-32:1) |

| Vacuum shaye | Zabin | ||||

| Mai canza allo | Daidaitaccen tsari | ||||

| Ruwan zobe granulation | Zabin | ||||

| Cold strand granulation | Zabin | ||||

| Ƙarƙashin ruwa granulation | Zabin | ||||

layin agglomeration mataki biyu

| Samfura | 70+90 | 100+120 | 120+150 | 150+180 | 180+200 |

| Fitowa (kg/h) | 110-180 | 200-300 | 300-450 | 500-650 | 700-850 |

| Amfanin wutar lantarki (kWh/kg) | 0.2-0.35 | ||||

| Babban iko (kW) | 30+22 | 75+37 | 90+45 | 110+55 | 160+75 |

| Agglomerator ikon (kW) | 30 | 55 | 75 | 110 | 132 |

| Matsakaicin diamita na waje (L/D) | 70 (25+12:1) | 100 (25+12:1) | 120 (25+12:1) | 150 (25+12:1) | 180 (25+12:1) |

| Vacuum shaye | Zabin | ||||

| Mai canza allo | 2 sets na daidaitaccen tsari | ||||

| Ruwan zobe granulation | Zabin | ||||

| Cold strand granulation | Zabin | ||||

| Ƙarƙashin ruwa granulation | Zabin | ||||

Rukunin samfuran

Kuna son Ƙara Sky zuwa Zanen ku?

Tuntube mu a yau don shawarwarin ƙira.