Injin Granulating PET Babban Ingantacce

Halaye

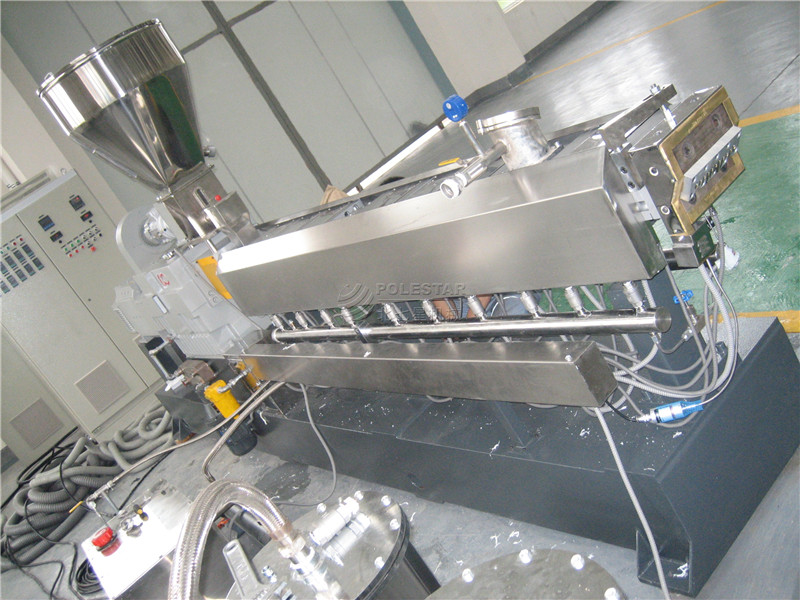

A PET pelletizer yafi kunshi da wadannan kayan aiki: extruder, na'ura mai aiki da karfin ruwa allo canji, strand yankan mold, sanyaya conveyor, bushewa, abun yanka, fan busa tsarin (ciyar da bushewa tsarin), da dai sauransu Yi amfani da layi daya tagwaye dunƙule extruder don samun daidai zafin jiki iko. , babban fitarwa tare da ƙananan amfani da wutar lantarki.

Aikace-aikace

Ana amfani da injin pelletizing na dabba don yin flakes na filastik PET a cikin pellet ko granule.Twin dunƙule extruder sake yin amfani da pelletizing tsarin ana amfani da sharar gida kayan, wanda bukatar high aiki yi na narkewa, volatilization, tacewa da dai sauransu.

Tsarin Tsari

Screw Feeder (ZABI) → Mai ba da ƙarfi → Parallel twin screw extruder → Mai canza matattarar ruwa → Mold head → tankin sanyaya ruwa → Filastik daidaitaccen abin yanka → Kammala tattara kayan samfur.

Cikakken Bayanin Kowane Abu

1. Screw Feeder: isar da tarkacen filastik cikin babban injin.

2. Ƙaddamar da Ƙarfin Ƙarfi: kayan abinci don fitar da sauri tare da saurin da aka tsara, ana iya daidaita saurin gudu.

3. Parallel twin dunƙule extruder: plasticizing abu da m gas.

4. High-gudun Net musayar tsarin da Die-head: tace kayan ƙazanta, don sa samar da karin kwanciyar hankali.

5. Tankin ruwa: sanyaya noodles na PET.

6. Filastik misali abun yanka: yanke PET noodles a cikin granuels.

Amfanin Gasa

1. atomatik PLC iko

2. Tare da sarrafa zafin jiki na mutum

3. M aiki & Barga yi

4. Ingantacciyar inganci, kariyar muhalli da ceton makamashi

Bayanan Fasaha

| Extruder | Saukewa: TSK35 | TSK50 | Saukewa: TSK60 | TSK65 | TSK75 | TSK95 |

| L/D(mm) | 24-56 | 24-56 | 24-56 | 24-56 | 24-56 | 24-56 |

| Matsakaicin gudun (rpm) | 600 | 500 | 300-500 | 400-500 | 400-500 | 300-400 |

| Ƙarfin Mota (kw) | 11-18.5 | 22-37 | 37-55 | 45-75 | 90-160 | 185-250 |

| Wutar lantarki (kw) | 16 | 24 | 30 | 34 | 45 | 60 |

| Matsakaicin fitarwa (kg/h) | 20-80 | 50-200 | 80-300 | 100-350 | 200-500 | 700-1200 |

Rukunin samfuran

Kuna son Ƙara Sky zuwa Zanen ku?

Tuntube mu a yau don shawarwarin ƙira.