Babban Ingantacciyar Injin PPR Pipe Extruder Machine

Bayani

PPR bututu extruder amfani a extrudering PPR, polyolefin da sauran thermoplastics.

PPR bututu extruder na iya sarrafa kowane nau'in samfuran filastik tare da na'ura mai taimako.

Kamar fim, bututu, mashaya, farantin karfe, zaren, ribbon, insulating Layer na USB, m kayayyakin da sauransu. Ana kuma amfani da extruder na PPR a cikin hatsi.

PPR bututu extruder zane ya ci gaba. Ƙarfin samar da shi yana da girma. Ƙirƙirar filastik yana da kyau, kuma amfani da makamashi yana da ƙasa. PPR bututu extruder rungumi dabi'ar haƙori mai wuya na kayan aiki don watsawa, yana da fa'ida daga ƙaramin amo, aiki mai santsi, babban kaya, tsawon amfani-rayuwa da sauransu.

Aikace-aikace

PPR bututu extruder ne yafi amfani don yin bututu, takardar, mashaya da sauran roba kayayyakin daga PPR kayan sanye take da daban-daban irin inji da kuma ƙasa.

Don SJ serial dunƙule extruder, da dunƙule diamita ne daga 20 zuwa 200mm, da dunƙule L / D ne 10-40. Kuna iya zaɓar nau'in extruder bisa ga samfuran ku, ƙayyadaddun bayanai da ƙarfin ku.

Tsarin ciyarwa yana amfani da YASKAWA, kuma babban ɗaukar hoto yana ɗaukar sassan Japan NSK na asali da aka shigo da su, mai fitar da kaya yana da ƙimar kuɗi mai kyau. mun kuma yi alƙawarin kyakkyawan sabis na tallace-tallace.

Bayanan Fasaha

| Diamita bututu (mm) | 16-63 | 20-110 | 75-160 | 90-250 |

| Extruder | SJ45 | SJ60 | SJ75 | SJ75 |

| Motoci (KW) | AC30 | DC75 | DC110 | DC110 |

| Iyawa(KG) | 60-100 | 100-150 | 250-300 | 250-300 |

| Matsakaicin saurin layin (m/min) | 10 | 6 | 6 | 6 |

Single Screw Extruder

Dangane da 33: 1 L / D rabo don dunƙule zane, mun ɓullo da 38: 1 L / D rabo. Idan aka kwatanta da 33: 1 rabo, 38: 1 rabo yana da amfani na 100% plasticization, ƙara yawan ƙarfin fitarwa ta hanyar 30%, rage yawan amfani da wutar lantarki har zuwa 30% kuma ya kai kusan aikin extrusion na layi.

Simens Touch Screen da PLC

Aiwatar da shirin da kamfaninmu ya haɓaka, da Ingilishi ko wasu harsuna don shigar da su cikin tsarin.

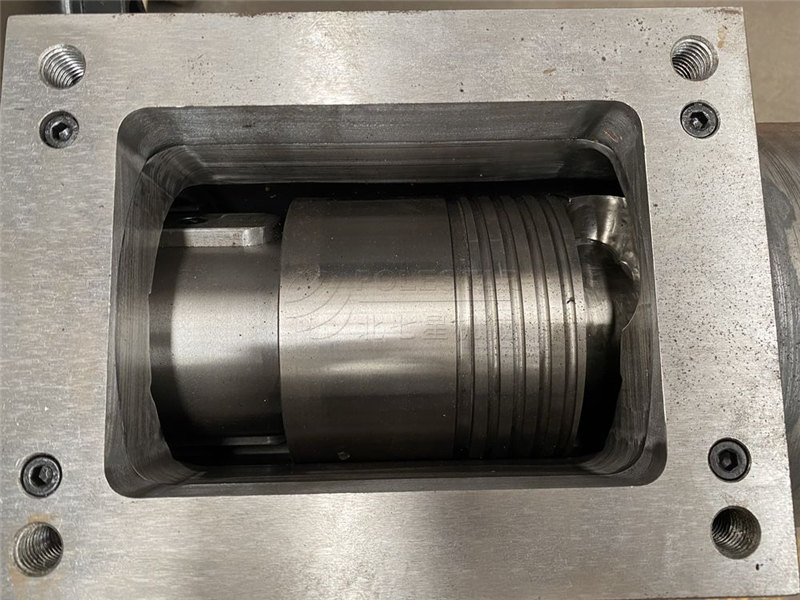

Zane na Musamman na Screw

An tsara dunƙule tare da tsari na musamman, don tabbatar da ingantaccen filastik da haɗuwa. Abubuwan da ba a narkewa ba ba za su iya wuce wannan ɓangaren dunƙule ba, mai kyau filastik extrusion dunƙule.

Karkataccen Tsarin Ganga

Sashen ciyar da ganga yana amfani da tsarin karkace, don tabbatar da ciyarwar kayan cikin kwanciyar hankali da kuma ƙara ƙarfin ciyarwa.

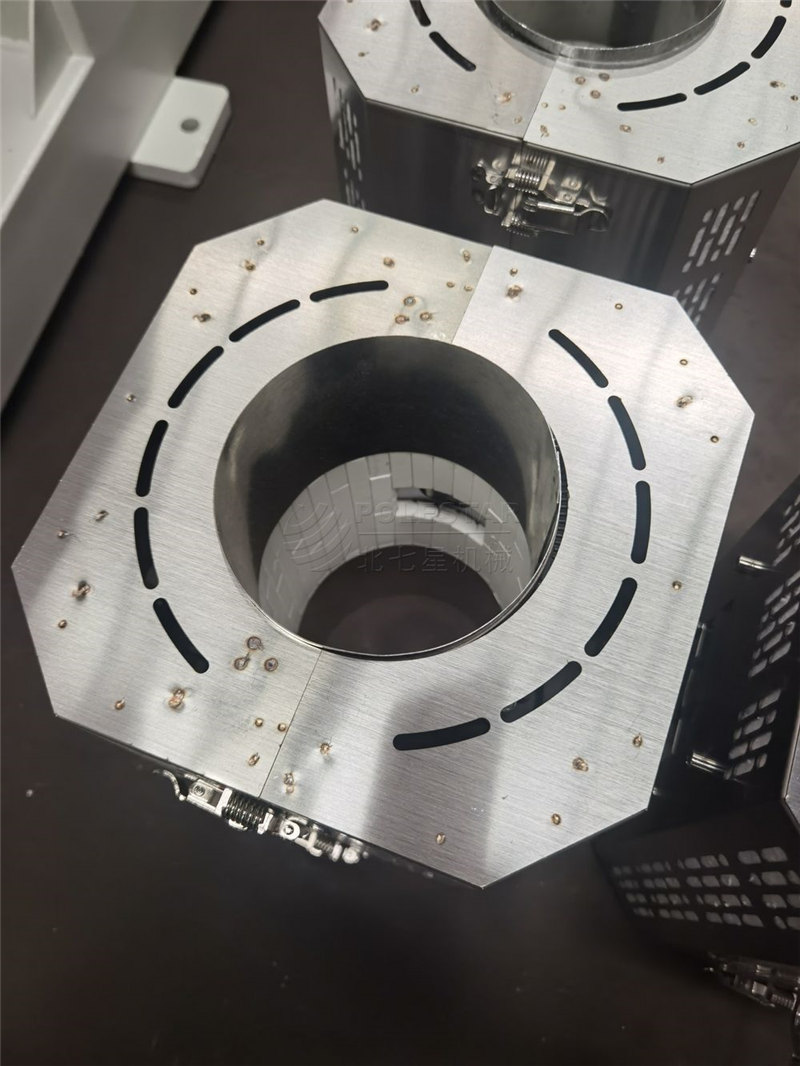

Tushen yumbu mai sanyaya iska

Injin yumbu yana tabbatar da tsawon rayuwar aiki. Wannan ƙirar ita ce haɓaka wurin da mahaɗar ke hulɗa da iska. Don samun sakamako mafi kyawun sanyaya iska.

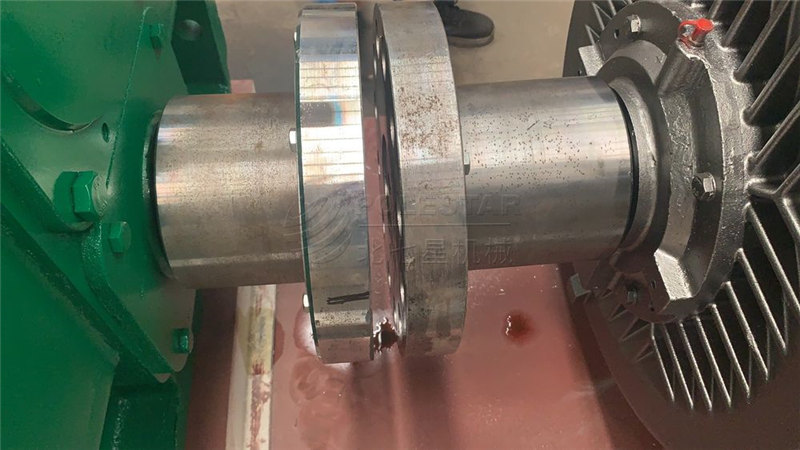

Akwatin Gear Mai inganci

Za'a tabbatar da daidaiton gear 5-6 da ƙaramar amo ƙasa da 75dB. Karamin tsari amma tare da babban juyi.

Rukunin samfuran

Kuna son Ƙara Sky zuwa Zanen ku?

Tuntube mu a yau don shawarwarin ƙira.